Fire-Resistant Boots

Why you need this: Because emergencies happen fast and rescue can be hours away, this emergency gear helps you stay safe and care for your family.Fire-Resistant Boots: The Complete Guide to Safer Steps in Hot, Hazardous Environments

Fire-resistant boots are specialized safety footwear designed to shield your feet from high heat, open flames, hot surfaces, and smoldering debris. Unlike ordinary work boots, they use materials and construction techniques that char instead of melt, insulate against radiant and conductive heat, and help reduce injury risks from burns, punctures, and slips. Whether you face occupational hazards or simply want a more resilient layer of protection for DIY projects and emergency readiness, fire-resistant boots can be a crucial part of your personal safety plan.

Why they matter is simple: foot injuries are common during emergencies and routine tasks. From stepping on hot metal shards after a garage mishap to crossing ash-covered ground during a wildfire evacuation, your footwear is often the first line of defense. The right pair helps you maintain traction, protect your toes, and limit heat transfer so you can keep moving safely when seconds count.

In everyday life, these boots can help during home repairs, outdoor cooking, vehicle maintenance, and storm cleanup. In more severe scenarios—like industrial incidents, building fires, or disaster response—heat-rated and flame-resistant footwear can literally make the difference between safe egress and severe burns.

How It Works

Fire-resistant boots combine smart materials with protective design. The goal is to reduce heat transfer, resist ignition, and prevent melting, all while offering the traction, stability, and impact protection you expect from quality safety footwear.

- Heat-tolerant uppers: Leather or engineered FR textiles that char instead of melt help protect against sparks, embers, and brief flame exposure.

- Insulating layers: Multilayer linings and thermal barriers slow heat conduction, keeping interior temperatures more manageable.

- Heat-resistant outsoles: Specialized rubber compounds (often rated for high temperatures) resist softening and provide traction on hot surfaces.

- Reinforced protection: Toe caps (steel or composite), puncture-resistant plates, and optional metatarsal guards defend against impacts and sharp debris.

- Secure closures and stitching: Heat-resistant threads, minimal exposed metal, and robust lacing systems maintain structure under stress.

- Moisture and oil resistance: Treatments and compounds that repel liquids help maintain grip and reduce deterioration.

Many pairs also carry recognized safety certifications that indicate impact protection, electrical hazard resistance (under dry conditions), slip resistance, and outsole heat tolerances. Checking these standards helps you match the boot to your specific risk profile.

When Fire-Resistant Boots Help Most

- Natural disasters: Wildfire evacuations, post-fire reentry, and cleaning up hot ash and embers; navigating debris after earthquakes or storms where hot surfaces or electrical hazards may be present.

- Home accidents: Grease flare-ups, chimney or fireplace embers, dropped soldering irons, hot coals from a grill or smoker, and accidental contact with heated tools or surfaces.

- Workplace scenarios: Welding, metal fabrication, foundry or glass work, roofing and asphalt jobs, HVAC and boiler rooms, commercial kitchens, and facilities with high-temperature processes.

- Vehicles and garages: Hot exhaust components, molten or heated metal fragments, sparks from cutting and grinding, battery thermal events, and roadside emergencies on hot pavement.

- Outdoor activities: Campfire management, brush clearing in hot, dry conditions, controlled burns under supervision, and handling hot equipment in fieldwork.

Strengths, Suitability & Limitations

Strengths

- Heat and flame resistance: Materials that char rather than melt provide a safer barrier than standard footwear.

- Improved traction: Heat-resistant rubber compounds maintain grip on hot, oily, or debris-littered surfaces.

- Impact and puncture protection: Safety toes and plates guard against falling objects and sharp debris common after fires or mechanical failures.

- Versatility: Suitable for a range of tasks from industrial applications to home maintenance and emergency kits.

What It’s Not For

- Extended direct flame immersion: These boots are not magical fireproof shields; intense or prolonged fire exposure can exceed design limits.

- Substitute for full PPE: They complement, not replace, proper protective clothing, gloves, eye and respiratory protection.

- Electrical work in wet conditions: Even with EH ratings, wet environments change risk profiles; follow relevant standards and procedures.

- Chemical hazards: Unless specifically rated, they are not designed for corrosives or specialized chemical exposure.

Limitations and safety considerations

- Heat ratings have limits: Outsoles and uppers are tested to specific temperatures and durations; beyond those, performance degrades.

- Adhesives and stitching can fail: Extreme heat or repeated exposure may weaken bonds and seams—frequent inspection is essential.

- Fit affects protection: Ill-fitting boots can cause blisters, reduce control, and slow egress in emergencies.

- Maintenance matters: Soot, oils, and caustic residues can accelerate wear if not cleaned promptly.

What to Look For When Buying Fire-Resistant Boots

A thoughtful purchase balances protection, comfort, durability, and compliance with applicable safety standards. Look for the features that align with your risks, not just marketing claims.

- Verified heat and flame resistance: Check for stated temperature ratings on the outsole and upper, and any certifications relevant to your industry or region.

- Uppers and lining materials: Quality leather or engineered FR textiles that resist ignition, paired with insulating liners that help slow heat transfer.

- Outsole compound: Heat-resistant rubber with oil and slip resistance; deep tread patterns for traction on ash, soot, and wet surfaces.

- Protective reinforcements: Safety toe caps (steel or composite), puncture-resistant midsoles, and optional metatarsal guards if your work involves overhead or frontal impact risks.

- Construction quality: Robust stitching with heat-resistant thread, reinforced randing, and durable bonding methods to better withstand thermal stress.

- Closure system: Secure laces, zippers, or buckles designed to stay functional under heat; minimal exposed metal reduces heat conduction.

- Height and coverage: Taller shafts help keep embers and hot debris out; consider your environment and mobility needs.

- Comfort and fit: Anatomical footbeds, arch support, and room for appropriate socks; adequate toe box space reduces fatigue and hotspots.

- Safety standards: Look for recognized impact, compression, and slip-resistance markings, and confirm any electrical hazard or heat-outsole ratings required for your job.

- Sizing and widths: Ensure availability of half sizes and wider widths if needed; a secure heel lock and stable platform improve control.

- Weight vs. protection: Heavier boots may offer more protection; ensure the balance suits your shift length and tasks.

- Red flags to avoid: Vague claims without specifications, suspiciously low pricing, thin outsoles, and poor stitching quality often signal imitations that won’t perform when it counts.

Placement, Storage & Readiness

Where you store your fire-resistant boots can determine whether you can access them quickly in an emergency and how long they last.

- Strategic placement: Keep a ready pair near exits, alongside other PPE, or in a go-bag for rapid evacuation; a dedicated garage or utility-room location works well.

- Vehicle readiness: If your work or region presents frequent fire risks, a stowed pair in your vehicle can be invaluable—protect them from excessive heat and direct sunlight.

- Clean and dry storage: Air-dry thoroughly after use; avoid radiators or open flames. Use newspaper or boot dryers designed for low-heat circulation.

- Shape retention: Boot trees or crumpled paper help maintain form and reduce creasing that can crack under stress.

- Routine inspection: Check soles for glazing, cracking, or delamination; examine stitching and closures; replace worn laces.

- Care products: Use cleaners and conditioners compatible with FR leather and materials; avoid petroleum-heavy products that can compromise fire resistance.

- Rotation: If used daily in hot environments, rotate between two pairs to allow full drying and prolong lifespan.

How to Use It Properly

- Match the boot to the task: Identify your heat exposure, impact, and slip risks; confirm relevant safety ratings before use.

- Inspect before wearing: Look for cuts, burns, loose soles, or failed stitching; ensure laces, zippers, and buckles function smoothly.

- Choose the right socks: Use moisture-wicking, heat-tolerant socks; avoid synthetics that melt easily under high heat.

- Put on and secure: Slide in with heel seated; tighten laces or fasten closures evenly for ankle support without restricting circulation.

- Test traction and comfort: Walk and flex to check for hotspots or slipping; adjust fit as needed before entering hazardous areas.

- Work smart around heat: Avoid prolonged standing on hot metal or asphalt; step carefully over embers and shield against sparks when possible.

- After exposure: Brush off ash and debris, check for damage, and clean per manufacturer guidance; let boots fully dry away from direct heat sources.

- Retire when compromised: Replace boots showing outsole glazing, deep cracks, delamination, crushed toe caps, or significant burn damage.

Safety reminder: Fire-resistant boots support overall protection but do not replace full PPE, training, or safe operating procedures. Always follow workplace and local safety guidelines.

Final Summary

Fire-resistant boots provide a vital layer of defense against burns, heat transfer, and debris in both everyday tasks and high-risk situations. From welding projects to wildfire evacuations, the right pair helps you stay on your feet, maintain traction, and keep moving when conditions turn hot and hazardous.

When you’re choosing a pair, focus on verified heat ratings, quality materials, solid construction, and proper fit. Store them where you can reach them quickly, maintain them after each use, and inspect them routinely. With thoughtful selection and care, fire-resistant boots can become one of the most reliable tools in your safety toolkit—supporting productivity at work and peace of mind at home.

Take the next step today: assess your risks, set your must-have features, and invest in well-built, heat-rated footwear that’s ready for real-world conditions.

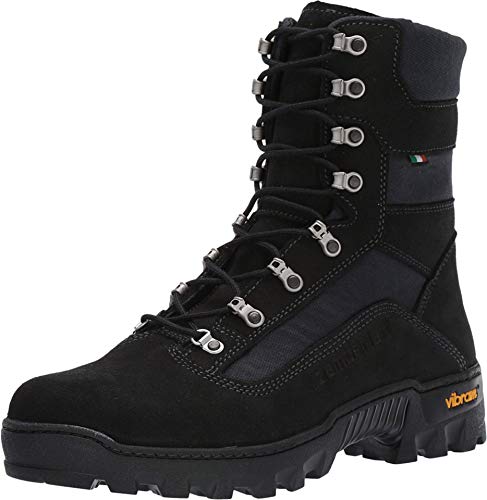

Zamberlan 5020 Extinguisher II WLF Best for most families

- Thermal barrier and heat-resistant outsoles slow heat transfer from hot surfaces and embers.

- Puncture plate and reinforced toe reduce injuries from nails, glass, and twisted metal.

- Slip-resistant tread maintains traction on ash, foam, oil, and wet concrete.

- Tall, fire-resistant uppers shield ankles and lower legs from sparks and abrasions.